|

EXTRUDER SCREW BARRELAt attitude plast, we offer extruder screw barrel to the customers across the Europe. As a core part of our products, the extruder screw barrel we manufacture is representing our ultra machining capability and a cutting-edge processing level at the frontfore of world!

Collect

产品编号 APLAST002

In order to follow up most of extruder brands, our screws and barrels are usually divided into 4 different types of geometries and designs as below. That means that our products could reach to a variety of plastics production applications.

Attitude Plast always procures and utilize most premium and durable steels material from the domestic or abroad. The body materials we're using have a series of good features: high hardness, low fragility and strong toughness.

A listing of quality materials we use as follows: ● nitrided steel: 38CrMoAla, 4140, SACM645 ● alloy structural steels: 40Cr, 42CrMo etc. ● tools steels: W6Mo5Cr4V2, SKD61, D2, DC53, H13 etc. ● alloy material: GH113 If you don't find a suitable material number above, please directly tell us the material you prefer. We are open with the selection of material according to your specific requirements! The nitriding process: Nitriding process is a most economic production process among all the wear-resistance processes. First of all, it could bring you the cost savings and it would also protect the screw and barrel from an impact of wear & abrasion, corrosion, high temperature & pressure when working with common plastics or virgin resins/polymers. The nitriding process is capable of reaching the following parameters in the sheet.

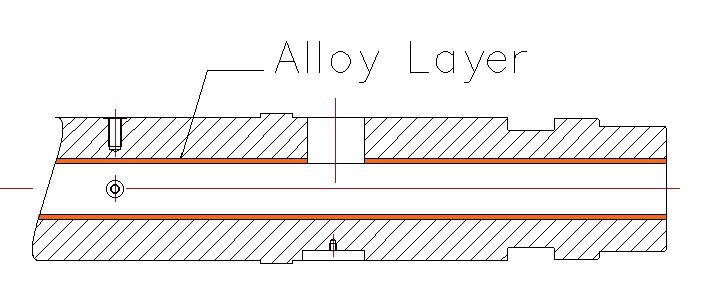

The bimetallic enhancements: The appearance of bimetal process is because of applying complex plastics material to the extrusion production. To get a high quality end plastic product, many extruders choose the virgin polymer with fillers or as a result of the profit drive, some manufacturers use 100% recycled plastic granules. The different production situations lead us to develop reinforced bimetallic products under the bimetallic processes: ● Fe-based bimetallic ● Ni-based bimetallic ● Alloy+T/C composites

|